SUS 304L stainless steel

SUS 304L, a low-carbon version of SUS 304 stainless steel, has a wide range of applications and excellent performance. It is mainly composed of 18% chromium (Cr) and 8% nickel (Ni), and reduces the carbon (C) content, making it more suitable for certain specific application scenarios. SUS 304L has received widespread attention for its excellent corrosion resistance, mechanical properties and diverse application fields.

SUS 304L material properties

SUS 304L is a high-quality austenitic stainless steel with excellent mechanical properties and corrosion resistance. Compared with SUS 304, its low carbon content makes it less likely to produce carbides during high-temperature welding and blunt edge processing. This makes SUS 304L more suitable in some special environments.

SUS 304L chemical properties

The chemical composition of SUS 304L is the cornerstone of its outstanding performance. 18% chromium gives it resistance to oxidation and corrosion, and 8% nickel gives it resistance to acidic and alkaline media. The low carbon content ensures that carbides are not easily produced at high temperatures and enhances corrosion resistance. In addition, other elements such as silicon (Si), manganese (Mn) and phosphorus (P) also play a role in adjusting the properties of the material.

SUS 304L chemical composition (%)

| ITEM | C | SI | MIN | P | S | CR | NI | N | OTHERS |

|---|---|---|---|---|---|---|---|---|---|

| Min | === | === | === | === | === | 17.50 | 8.00 | === | === |

| Max | 0.03 | 0.75 | 2.00 | 0.45 | 0.030 | 19.50 | 12.00 | === | === |

SUS 304L mechanical properties

SUS 304L is known for its excellent mechanical properties. At room temperature, it has a tensile strength of approximately 485 MPa and a yield strength of approximately 170 MPa, which enables it to withstand loads and stresses in structures and parts. The low carbon content ensures its stability during high-temperature welding, allowing it to perform excellently in various environments.

304L mechanical properties

| MIN | MAX | ||

|---|---|---|---|

| Yield Strength (N/mm2) | 0.20% Y.S. | 205 | N/mm2 |

| 1% Y.S. | === | ||

| Tensile Strength (N/mm2) | 520 | N/mm2 | |

| Elongation % | 40 | === | |

| Hardness Test | HRB | === | 90 |

| HV | === | 200 |

SUS 304L physical properties

The physical properties of SUS 304L make it widely used in many fields. Its density is approximately 7.9 grams/cubic centimeter, which contributes to lightweighting in structural design. In addition, the thermal expansion coefficient of SUS 304L is relatively stable, which helps reduce problems that may occur under temperature changes. Its superior thermal conductivity and electrical conductivity also make it widely used in heat exchange, electronic equipment and other fields.

SUS 304L corrosion resistance

The corrosion resistance of SUS 304L is one of its greatest features. The presence of chromium and nickel gives it excellent resistance to oxidizing acids, alkaline media and some chemicals. In addition, the low carbon content makes it less likely to produce carbides during welding, enhancing its stability in corrosive environments. This makes SUS 304L widely used in fields with high corrosive requirements such as chemical industry and food processing.

SUS 304L product application

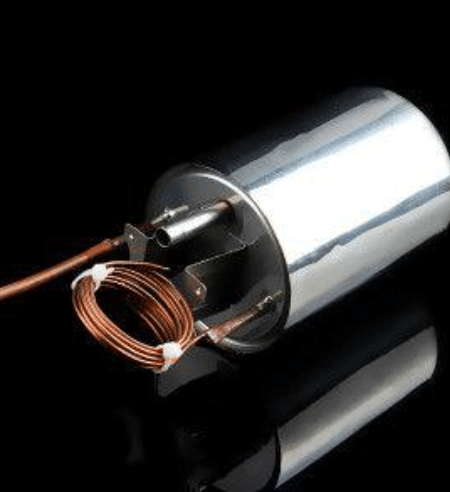

The wide application of SUS 304L stainless steel makes it one of the preferred materials in many fields. In the food processing and catering industries, it is used to manufacture stainless steel kitchenware, containers and equipment to ensure food quality and hygiene. In the chemical industry, SUS 304L is widely used in manufacturing containers, pipes and instruments to deal with corrosive media. In high temperature environments, it is used in heat exchangers, automobile exhaust systems, etc. In addition, SUS 304L is also used in high-demand fields such as manufacturing fine precision parts, high-pressure vessels, and nuclear reactor components.

In summary, SUS 304L stainless steel has become an indispensable material in modern industry and construction due to its superior performance and diverse application fields. Whether in the fields of precision instrument manufacturing, architectural design or chemical industry, SUS 304L plays a key role and continues to promote the advancement of technology and innovation.